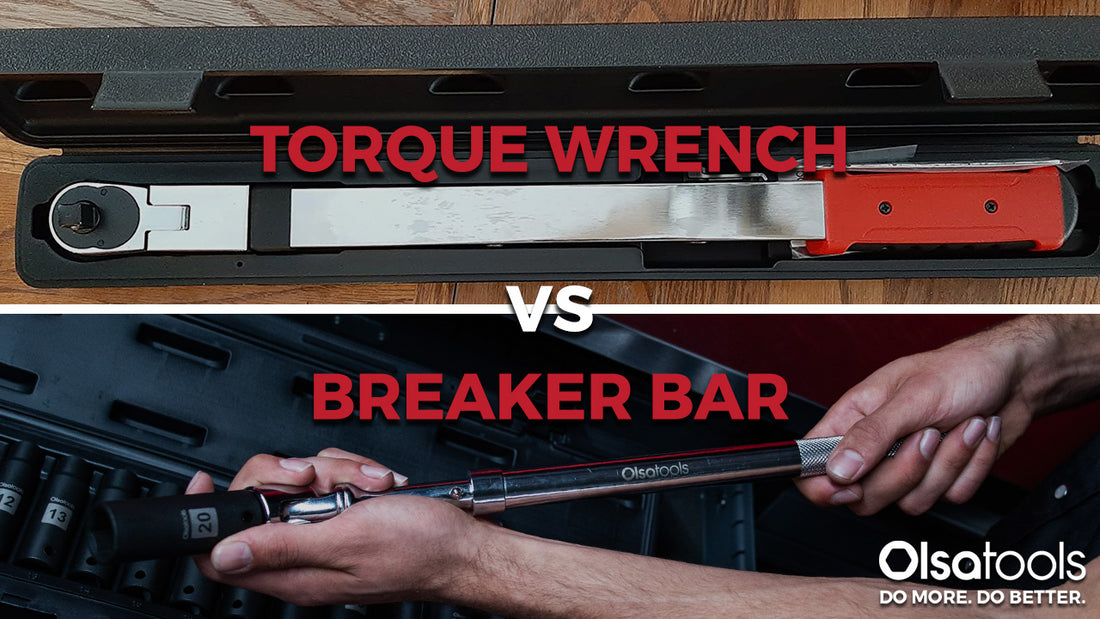

Working with nuts and bolts can be challenging, so having the most convenient tools for the job is essential to complete your fastening tasks without aggravation or stress. Torque wrenches and breaker bars are two of the most common working pieces you should not cut corners with. Those tools are particularly handy and have similarities that usually make people ask: “can I use a torque wrench as a breaker bar?”.

We will dig into this topic by telling you some basic distinguishing features, resemblances, and use cases to know if they can be used for the same purposes.

Torque Wrench & Breaker Bar Purpose

Each tool is designed with a specific objective: breaker bars can "break" tight, frozen, and rusted fasteners free, which otherwise could not be undone by smaller tools like ordinary wrenches and ratchets.

When a ratchet can not do the job, a breaker bar is a go-to tool when you need higher leverage and torque power.

Torque wrenches, on the other hand, are engineered with a mechanism that exerts a specific amount of torque onto a fastener; which makes them the handiest tools when over-tightening situations are simply not an option; like while working with spark plugs, lug nuts, or for building or assembling engines.

Torque Wrench & Breaker Bar Safety

It is fair to say that torque wrenches are super safe to use!

The likelihood of a torque wrench having a catastrophic failure, breaking, or stripping a bolt under maximum torque is minimum, but only if you don’t compromise their torque capacities.

Breaker bars are built to handle more generous torque limits, and their applications are far more intense.

Those tools are designed for heavier-duty tasks, this means you get increased chances of shearing off a fastener, causing injury, or having a catastrophic failure while performing hardcore tasks.

So, beware of managing the tool securely and using safety glasses while working on heavier-duty projects.

Torque Wrench & Breaker Bar Control & Limits

This Olsa Tools extendable breaker bar is built using industrial-grade steel that has been appropriately heat-treated, it can handle 450 ft/lbs of torque, an extremely powerful tool!

However, numerous breaker bars on the market are able to handle up to 2,000 ft/lbs. But the strength or physique of the person using the tool will also determine the amount of torque applied.

A manual torque wrench like this Olsa Tools split beam torque wrench is constructed with a maximum torque strength of 250 ft/lb.

They might not deliver the amount of torque as their breaker bars counterparts, but when it comes to control they definitely take the win.

Their design creates a loud click sound and splits at the joint when you reach the desired torque value, which gives greater control over the tool while helping you complete tasks accurately.

The torque wrench is accurate up to +/-4% across the entire torque range. What a precise tool!

Price Point

This is probably the single most differential factor. Here, breaker bars beat torque wrenches thanks to their non-ratcheting mechanism. It is simpler and easier to produce, making them far less pricey and more “replaceable” as they’re more budget-minded.

Meanwhile, torque wrenches are significantly pricier because of their specialized inner mechanism, which is more accurate, precise, and sophisticated. For companies this complex design calls for more time and better resources to produce the tool that best meets their customers’ needs. In simple words, a torque wrench goes a long way in terms of functionalities, and this is the main reason their price point is “less” affordable compared to other fastening tools.

Can You Use a Torque Wrench as a Breaker Bar?

This is a big no-no! We’ve explained now how to use a torque wrench and a breaker bar, both products deliver extremely professional results when used for their intended purposes. The problem with working on hardcore projects using torque wrenches is that you can push them easily beyond their capabilities. This can break the internals and damage the calibration of the wrench.

Considering their price, you don’t want to work on extreme heavy-duty projects with a tool that is supposed to be used for more precise applications. Plus, if you want to increase the longevity of your torque wrench, simply leave this to your go-to breaker bar.

Final Thoughts

Is not that either tool is “better” or “worse”, but simply that you’ll find yourself working on specific tasks where one is handier than the other. Does the project require a high degree of accuracy? A torque wrench is your best pick. Want to break loose very tight fasteners? Use a breaker bar. Professional mechanics have both as they are worth having for their convenience and ease of use.